|

The Digibend 720 and Digibend 720 CNCare full

featured, heavy duty benders, which are ready to take on your toughest jobs.

Technical description

- EUROMAC’s hydraulic

cylinders are permanently integrated into a solid and normalized

Meehanite® steel casting (65 N/mm²) for all Digibend models. Each frame has been

designed with detailed finite element computations to achieve the best rigidity

and dampening.

- The cylinder and the frame form a working unit and are machined in one setup and operation to assure you the maximum accuracy

and reliability (patent pending).

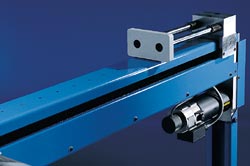

- Fast set-up tool indexing

systems are a standard feature on the Digibend. Four different tool

clamping systems can be integrated into the wide machine table as well as into the

moving ram:

A. Rapid Set-Up bending pin Ø 80 mm.

B. 5 aligned clamping pins Ø 80 mm.

C. 5 Guide holder placed inside the structure for 415 mm. high bending tool.

- Ram is equipped with hardened T-slots

to hold tooling accurate over a long time.

- All working parts are hardened and

precision ground.

- Thanks to the many types of tooling available,

you can accomplish nearly any bending task in minutes, from heavy plate bending,

flat edge bending, punching, shearing to straightening and tube bending.

- The precision back gauge will index your

parts with a repeatability of +/- 0.2 mm.

- The operator may select between two working speeds

and between single stroke, single step and automatic mode.

- The ram will automatically slow down near

the bending point, programmable at operators choice between 0 and 50mm.

- The ram speed is adjustable between 7 and

23 mm per second on the forward stroke.

- The hydraulic pressure can be controlled

between 10 metric ton and 72 metric ton.

- Easy, intuitive programming of all working

parameters in many languages is available: English, French, German, Spanish, Italian,

Dutch, Danish, Swedish, Japanese and many more.

- The stroke is electronically controlled

and displayed on a digital read out.

- The control can store parameters for up to 99 bends

which can be combined into up to 50 bending sequences with a maximum of 80 bends

each.

- The control display reads out all bending

parameters including forward/return stop and actual ram position. A piece counter

lets you keep track of your work progress.

- The maximum bending capacity for work pieces

up to 200 mm wide is 20 mm in mild steel. Thinner gauges up to 6 mm can be bent

up to 415 mm in width.

|

Technical Details |

Digibend

160

|

Digibend

360

|

Digibend

720

|

|

Hydraulic Pressure (Tons) |

16

|

36

|

72

|

|

Length of Stroke (mm.) |

200

|

250

|

350

|

|

Oil Tank Capacity (Lt.) |

25

|

ca. 60

|

100

|

|

Maximum Working Speed (mm./sec) |

10

|

10/24

|

10/23

|

|

Minimum Working Speed (mm./sec) |

2

|

6

|

7

|

|

Return Speed (mm./sec) |

28

|

60

|

45

|

|

Fixture points |

No.2 - Ø 50

No.1 - Ø 80

|

No.3 - Ø 50

No.1 - Ø 80

|

No.6 - Ø 80

|

|

Max. Oil Pressure (Bar) |

250

|

260

|

260

|

|

Working Height (mm.) |

900

|

900

|

900

|

|

Working Table Dimension (mm.) |

480 x 920

|

580 x 1.170

|

650 x 1.520

|

|

Overall Dimensions (L x W x H) (mm.) |

580 x 950 x 1.100

|

680 x 1.170 x 1.130

|

750 x 1.520 x 1.170

|

|

Weight (kg.) |

390

|

900

|

1.800

|

|

3-Phases Motor (Hp)-(Kw) |

2 - 1,5

|

5,5 - 4

|

5,5 - 4

|

|

Bending Height (mm.) |

200

|

200

|

200

|

|

Extra High Bending (mm.) |

/

|

H=415

|

H=415

|

|

Shearing Tool max. Thickness 12 mm. |

/

|

H=150 mm.

|

H=150 mm.

|

|

Punching Tool max. Thickness 10 mm. |

/

|

Ø 30 mm.

|

Ø 30 mm.

|

|

Straightening (mm.) |

H=200 mm.

|

H=200 mm.

|

H=200 mm.

|

|

Two Jaw Bending Tool

|

/

|

Ø 60 mm.

|

Ø 60 mm.

|

|

Rotary Bending Tool |

Ø 50 mm.

|

Ø 50 mm.

|

Ø 50 mm.

|

|

Wyvern Fabricating Solutions

1257 Sanguinetti Road #159,

Sonora, Calif. 95370 Phone (209) 559-9150 |

|